Danoil family of Dantec composite hoses come in 3 grades; Danoil 3 (light hydrocarbons) Danoil 7 (Heavier hydrocarbons) Danoil 9 (Biofuel, Aromatics, Solvents).

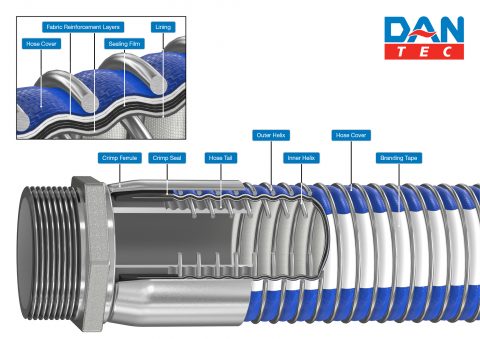

Both the Danoil 3 and Danoil 7 hoses, which are Dantec’s recommended hydrocarbon transfer hoses, are manufactured from multiple layers of polypropylene fabrics and films.

The inner helix is available in galvanised steel and aluminium. The outer wire is available in galvanised steel, and only in the case of the Danoil 3 is also available in aluminium.

Danoil 9 range is a polyamide (nylon) lined version of the Danoil 7; This hose is used for products with high aromatic content and biofuels. The inner helix is available in 316 stainless steel, galvanised steel and aluminium, with the outer wire available in 316 stainless steel and galvanised steel.

Danoil 3 range is a robust but light weight hose, which is only available as a 10.5 bar standard duty hose and is mainly used in gravity to low pressure applications, such as road tanker deliveries.

Danoil 7 and Danoil 9 range are both 14 bar, tough high strength transfer hose and they are available in both standard and heavy duty.

Standard duty version is used in rail car unloading and in plant transfers. Heavy duty is available for ship to shore and marine applications.

INNER WIRE HELIX:

Stainless Steel: Premium choice, excellent chemical resistance, best mechanical strength. (Danoil 9SG, Danoil 9SS)

Galvanised Steel: Economical choice, good mechanical strength. (Danoil 3GG, Danoil 7GG, Danoil 9GG) Not to be used with Biofuels

Aluminium: Lightweight choices for hoses were weight is an issue (Danoil 3AA, Danoil 3AG, Danoil 7AG, Danoil 9AG)

OUTER WIRE HELIX:

Stainless Steel: Premium choice, excellent chemical resistance, best suited to weathering and external conditions (Danoil 9SS)

Galvanised Steel: Economical choice (Danoil 3AG, Danoil 3GG, Danoil 7GG Danoil 9AG, Danoil 9SG)

LINER:

Polypropylene: All hydrocarbon products (D3AA, D3AG, D3GG, D7AG, D7GG)

Polyamide: Excellent resistance for high aromatic solvents, MTBE, and biofuel (D9AG, D9GG, D9SG, D9SS)