Home > Products > Liquified Gas Hose > Danchem Pa Ss 100 Cryogenic Hose

Danchem PA SS 100 Cryogenic Hose

BS EN 13766:2018*

IMO Code Gas Carrier Code

| Bore Diameter |

Max. Working Pressure |

Bend Radius |

Weight |

| INS |

MM |

BARS |

PSI |

INS |

MM |

KG/M |

| 1 |

25 |

25 |

370 |

4.0 |

100 |

1.0 |

| 1.5 |

38 |

25 |

370 |

5.5 |

140 |

1.5 |

| 2 |

50 |

25 |

370 |

7.0 |

180 |

2.5 |

| 2.5 |

65 |

25 |

370 |

8.0 |

205 |

3.3 |

| 3 |

75 |

25 |

370 |

11.0 |

280 |

4.5 |

| 4 |

100 |

25 |

370 |

15.5 |

395 |

7.5 |

| 6 |

150 |

25 |

370 |

20.0 |

510 |

13.5 |

| 8 |

200 |

25 |

370 |

30.0 |

760 |

18.5 |

| 10 |

250 |

25 |

370 |

36.0 |

915 |

25 |

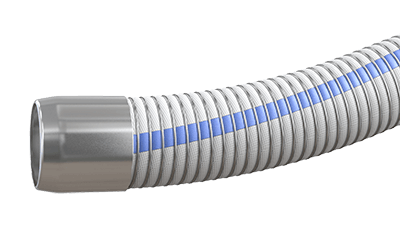

CONSTRUCTION:

1. Inner Wire Helix: 316 Stainless Steel High Tensile Strength Wire

2. Lining: Polyamide Cloth

3. Sealing Film: Polyamide Film

4. Reinforcements: Polyester Cloth

5. Cover: Polyamide Cloth

6. Blue Ribbon: Identification purposes

7. Outer Wire Helix: 316 Stainless Steel High Tensile Strength Wire

SAFETY FACTOR:

5:1* (Class A, Type 1 4:1, Class B, Type 1 5:1)

TEMPERATURE RANGE:

-104°C to +80°C

N.B. It is important to advise Dantec of the full working parameters when ordering Composite Hoses (medium, working temperature and working pressure). Working pressure rating stated above is based on transferring product at ambient temperatures (21°C/70°F). Elevated temperatures and end fitting ratings can severely reduce the working pressure of a hose assembly. Please consult Dantec technical sales with your requirements.